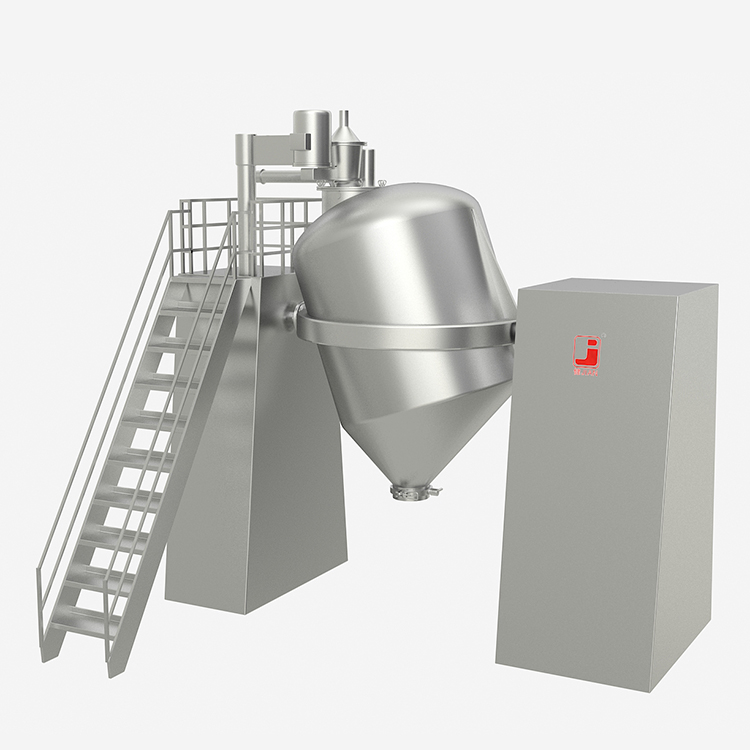

Chongqing Pharmaceutical Machinery Exhibition has come to an end. During the three-day exhibition, Jianpai...

1. Introduction

When it comes to size reduction equipment, many people use the terms grinders and pulverizers interchangeably....

In the pharmaceutical and nutraceutical industries, tablet coatings play a vital role in enhancing drug...

1. Introduction

1.1 Brief Explanation of Tablet Coatings in the Pharmaceutical Industry

In the pharmaceutical...

No posts found

ABOUT US

About Us - Introducing our team,

mission, and values.

- Pharmaceutical Industry

- Food & Confectionery Industry

- Lithium Battery Materials Industry

- Chemical Industry

Pharmaceutical Industry

Food & Confectionery Industry

Lithium Battery Materials Industry